Screening Solutions Built Around Your Process

Screening

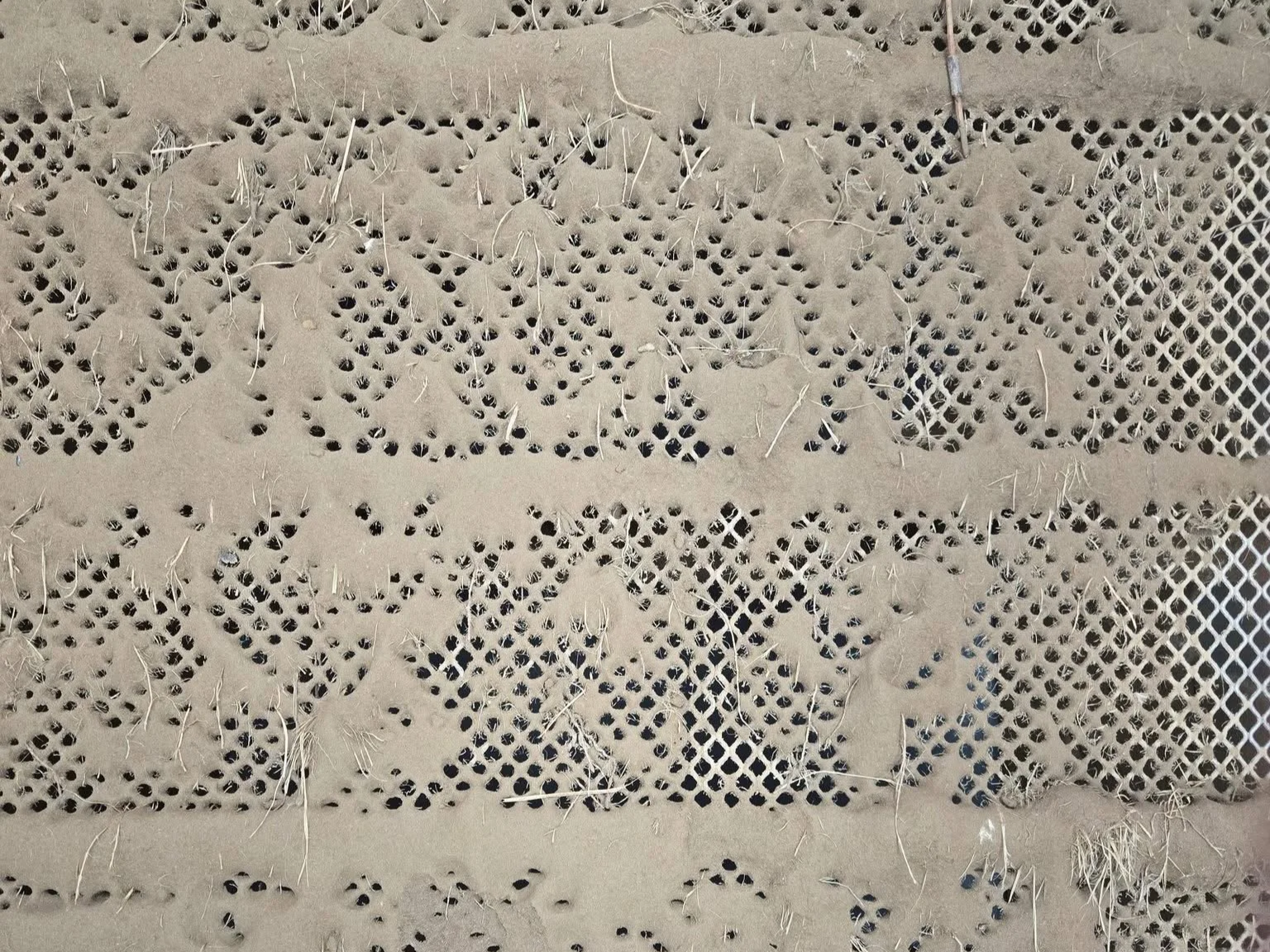

Screening is a critical step in material processing, separating material by size to ensure product meets specification and production stays efficient. When screening performance suffers, it can slow throughput, create off-spec material and increase wear throughout the system.

At Nor’East Equipment, we focus on screening solutions that match your material, tonnage, and operating conditions; not just the machine.

TYPES OF MATERIALS THAT CAN BE SCREENED

Aggregates

Quarry stone

Sand and gravel

Organics including Mulch, Compost and Topsoil

Trash and Waste

Recycled materials including metal

Specialty and industrial materials

When to Review or Upgrade Your Screening Process?

You may benefit from a screening review if you’re experiencing:

Ongoing maintenance issues

Reduced production rates

Changing material characteristics

New product specifications

Expansion or plant modifications

Common Screening Challenges We Help Solve

Inconsistent material sizing

Reduced throughput or bottlenecks

Blinding or pegging issues

Excessive wear on decks and components

Frequent downtime or maintenance

Poor integration with upstream or downstream equipment

Our Screening Solutions

We provide practical screening solutions designed to improve accuracy, efficiency, and uptime across a wide range of applications.

Screening Equipment Options

Inclined and horizontal screens

Dry and Wet screens

Portable and stationary systems

Wear Parts & Components

Screen media and decks

Liners and wear protection

Replacement components

Application & Process Support

Screen sizing and configuration guidance

Media selection based on material type

Throughput and efficiency optimization

Integration with crushing, washing, and conveying systems

Why Nor’East?

Hands-on industry experience

Practical, honest recommendations

Solutions matched to real operating conditions

Responsive support and follow-through

Long-term partnership beyond the sale

Not sure if your screening setup is working as well as it should?

Talk with a specialist about improving accuracy, efficiency, and uptime.